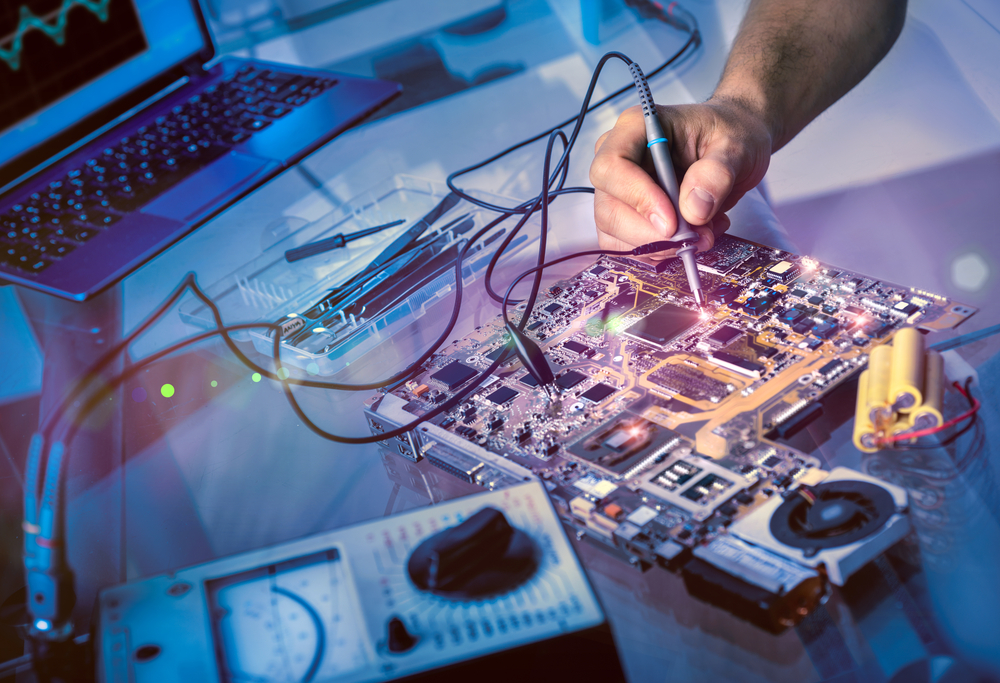

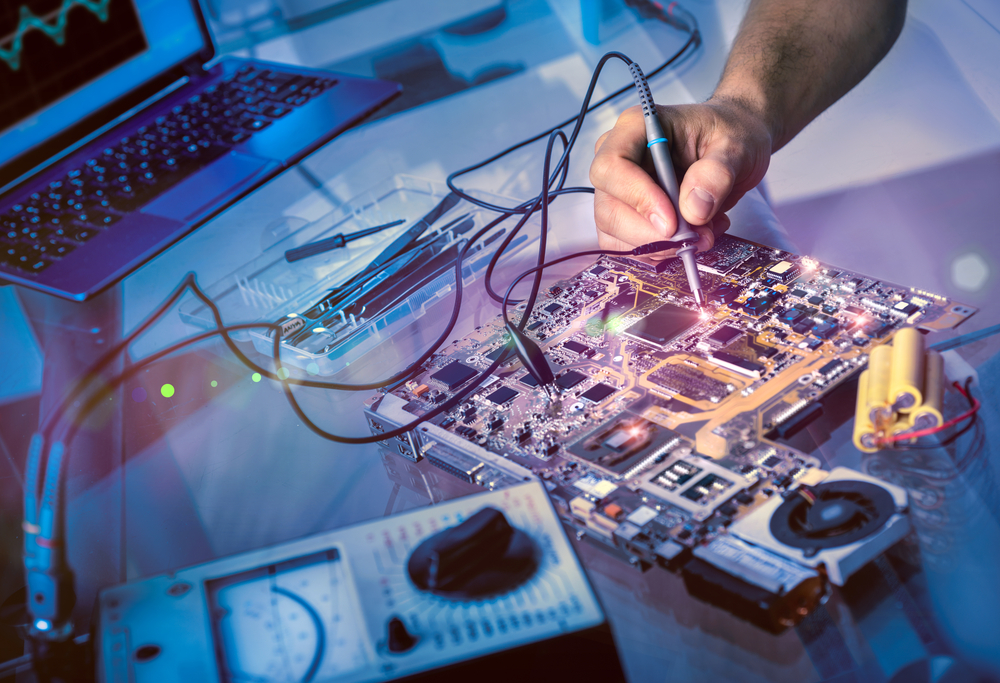

Engineering Services

We deliver market-leading, first-rate consultancy and design solutions. We supply Project Management, Systems Integration, Quality Control and our aftercare includes thorough Documentation and world-class Technical Support.

Some of Radio Systems most notable successes have evolved from a Consultative Sales approach. Sometimes projects are well defined from the outset with document sets including detailed Technical Specifications but sometimes only the Operational requirements are defined without any prescribed technical solution.

The Radio Systems R & D team has a long-standing reputation for taking an Operational Specification and translating it into a technical solution. For this type of Client and requirement, Radio Systems has a flow chart for order intake.

Each stage is managed, documented and is Client inclusive. Commercial risk forms part of Radio Systems internal processes but any external costs are never applied retrospectively, only by prior agreement and only then commensurate with the complexity of the project-specific order intake process.

As much as Radio Systems project documentation is enshrined in its ISO9001 procedures, we adopt a flexible project-specific approach to the subject. Broadly the scale of documentation has to be commensurate with project size, complexity and be in compliance with any externally derived specification requirements. Read more…

As much as project order intake has a structured process, so has order processing. However, in recognising the wide range of projects that Radio Systems undertakes, the structures that apply to each have to vary. For example, the way in which an order against an in-house design is processed has by its nature to differ from an order against a pre-defined specification. Read more…

Radio Systems is ISO9001, ISO14001, OHSAS18001 certified and WEEE registered. In addition, Radio Systems has a documented policy on Corporate and Social Responsibility.

Each project that Radio Systems undertakes will follow ISO9001 procedures and have its own Quality Plan.

In terms of product quality control, nothing is shipped from Radio Systems that is not individually tested. We do not rely upon production line batch testing. Each individual item is formally tested in our workshops. It is then shipped if ordered as a discrete item or passed to the Production team to be included as a component part of a system undergoing factory build.

Once parts that have been individually tested, have been built into a system at the Radio Systems factory and the whole system configured, it is tested with a suite of calibrated test equipment and where applicable, a representative mobile terminal fleet and line connected equipment.

After a period of soak testing, documented in-house Pre–FAT and Client witnessed FAT are conducted.

Following on-site commissioning and soak testing, a formal documented SAT is conducted.

In an increasingly competitive and cost-conscious market place areas of wastage and risk have become ever important. In the past, common practice would have been for Clients to obtain say radio equipment from a radio specialist, CCTV from a CCTV specialist, networking equipment from an IT supplier etc. Whilst this approach resulted in perfectly serviceable subsystems, integration into a single coherent system left split accountability and at worst incompatibility. Read more…

Post-sales support is important to Radio Systems, characterised by long term Client retention, repeat orders and high rates of aftercare satisfaction.

We have numerous support and maintenance contracts of varying terms, ranging from office hours telephone support to 24/7/365 on-site support. Read more…